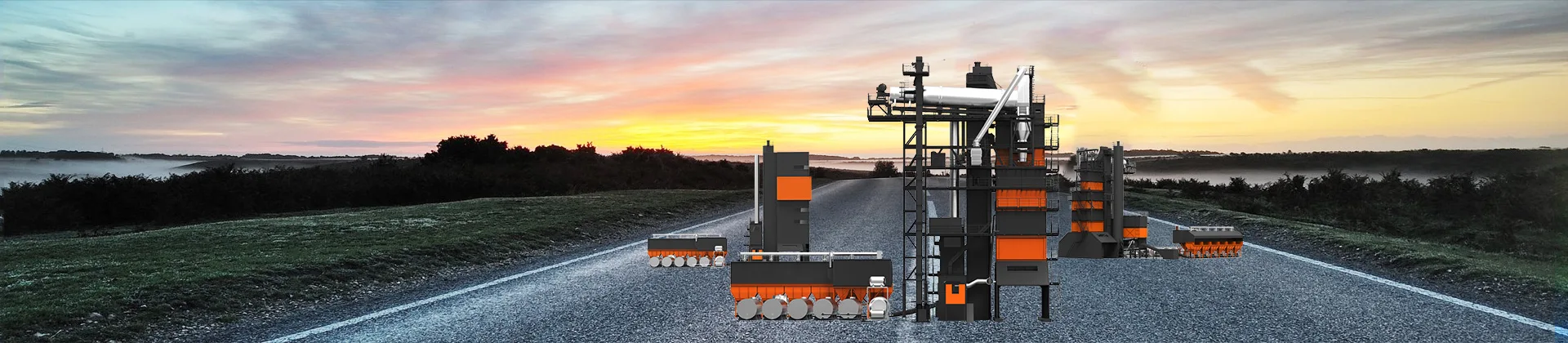

LB Series (Without Finished Product Silo)

Product Features

Compact Design

Designed without a finished product silo, the equipment features a streamlined configuration, minimal footprint, and optimized space utilization.

Drying System

The drying drum, burner, and baghouse dust collector are integrated into a single unit, reducing space requirements and improving thermal efficiency. The drum and blades are made of wear-resistant alloy materials, while the rings and rollers are forged for durability. The exterior is insulated with aluminum silicate wool and clad in stainless steel, ensuring reduced heat loss, high efficiency, environmental protection, and extended durability.

Dust Collection System

The modular dust collection system is installed directly above the drying drum, reducing land usage and heat loss through ducting. This compact design also allows for fast and easy relocation.

Screening System

The vibrating screen is powered by dual vibration motors from an Italian-imported brand, providing maintenance-free operation. The screen mesh features a pull-out installation design, allowing for quick and easy replacement. Additionally, the outer casing is insulated, offering energy savings and noise reduction.

Mixing System

The twin-shaft compulsory mixer is driven by gear-synchronized shaft-mounted reducers, ensuring high transmission efficiency and easy maintenance. The blade arrangement has been optimized through multiple tests to enhance mixing efficiency. Advanced manufacturing techniques ensure the stability and reliability of the equipment. A mechanical safety lock is installed on the maintenance doors to protect operators.

- Thermal Oil Heating System: Provides insulation for the asphalt.

- Additive & RAP Integration: Equipped with additive and recycled material feeding interfaces for future expansion.

Burner System

The self-developed low-pressure medium atomization burner features digitally controlled oil pressure and frequency for precise air-fuel ratio adjustment. The flame size is dynamically optimized to match the drum parameters, reducing fuel consumption. The integrated control system ensures seamless operation with the mixing plant.

Compatible Fuels: Diesel, Heavy Oil, Natural Gas.

Foamed Asphalt Warm Mix System

The modular design allows for quick installation. The imported diaphragm plunger pump delivers high-pressure, stable water as the foaming medium. The specialized mixing device generates a large volume of micro-foam within the asphalt, enabling low-temperature mixing while ensuring paving and compaction quality. This significantly reduces fuel consumption.

Control System

The dual-redundant control system enables button-free operation. The PLC-based full automation ensures simple, intuitive, and reliable production.

- Advanced Fault Prediction & Auto Diagnosis: Provides real-time monitoring and alerts.

- Remote Maintenance Support: Ensures easy operation, convenient maintenance, and high system stability.

This optimized design ensures the highest efficiency, lowest environmental impact, and seamless operation for modern asphalt production.