Crushing and Screening Equipment |

Equipo de Trituración y Cribado |

Equipamentos de Britagem e Peneiramento

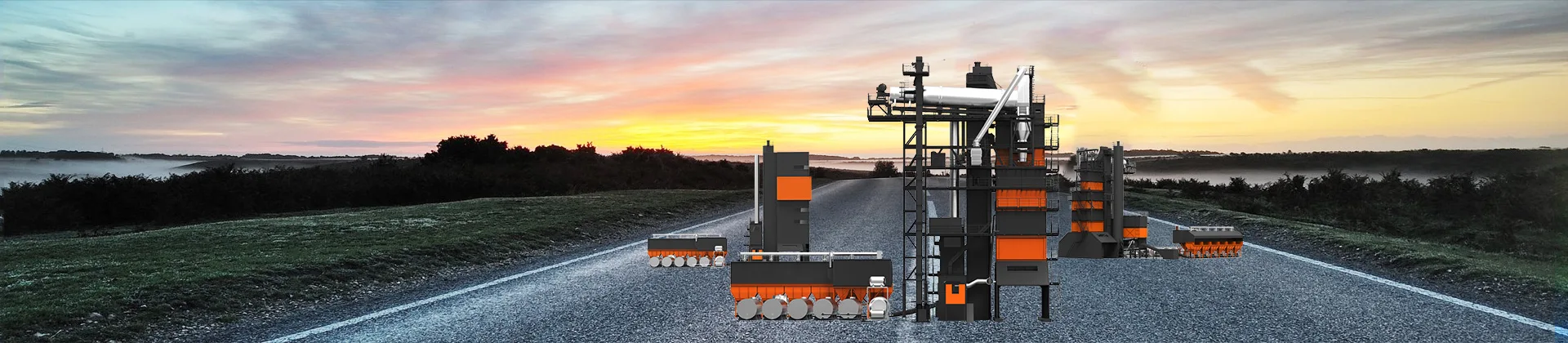

Product Introduction

RPS100 RAP Roller Crushing and Screening Equipment is a newly designed specialized crushing and screening product by Fujian Tietuo Machinery Co., Ltd.. It is developed based on years of experience in asphalt plant hot recycling equipment and is tailored to meet the specific requirements of RAP (Reclaimed Asphalt Pavement) material handling in Global.

Advantages of Roller Crushing and Screening Technology

Durable Single-Roller Crusher:

- Equipped with protective plates made of wear-resistant materials to protect standard blades.

- High crushing capacity, excellent wear resistance, and easy replacement enhance the equipment's service life.

Low Dust Emission:

- The low-speed main shaft effectively reduces dust emissions during operation.

Floating Double-Roller Crushing:

- The floating double-roller design effectively prevents sudden equipment failures caused by oversized RAP materials.

Interlaced Wear-Resistant Teeth Plates:

- Interlaced wear-resistant teeth plates effectively crush RAP materials without causing material sticking.

High-Frequency Vibrating Screen with Anti-Clogging Technology:

- Combines high-frequency vibrating screen with anti-clogging mesh technology to effectively solve fine aggregate adhesion issues.

Durable Single-Roller Crusher:

- Equipped with protective plates made of wear-resistant materials to protect standard blades.

- High crushing capacity, excellent wear resistance, and easy replacement enhance the equipment's service life.

Low Dust Emission:

- The low-speed main shaft effectively reduces dust emissions during operation.

Floating Double-Roller Crushing:

- The floating double-roller design effectively prevents sudden equipment failures caused by oversized RAP materials.

Interlaced Wear-Resistant Teeth Plates:

- Interlaced wear-resistant teeth plates effectively crush RAP materials without causing material sticking.

High-Frequency Vibrating Screen with Anti-Clogging Technology:

- Combines high-frequency vibrating screen with anti-clogging mesh technology to effectively solve fine aggregate adhesion issues.

Working Principle of Roller Crushing and Screening System

The RPS100 Crushing and Screening System is designed to screen RAP materials reclaimed from excavation or milling according to size specifications. Oversized materials are sent to a secondary crusher for further crushing before screening.

For large RAP blocks obtained from mechanical excavation:

- Processed through a primary roller crusher with a screw main shaft and hydraulic pushing device.

- The crushed materials are then stored in a cold feed bin.

For milled RAP materials:

- Directly fed from the cold feed bin to the vibrating screen for classification.

- Classified materials are separated into two or more stockpiles.

- Oversized RAP materials are crushed by the double-roller secondary crusher, then conveyed by belt to the vibrating screen for further sorting until they meet the required specifications.

Primary Roller Crusher

- Screw Crushing Roller and Hydraulic Pushing Device:

- Work together to efficiently crush large RAP blocks.

- Standard Crushing Blades:

- High wear resistance and easy replacement.

- Spring Tensioning Device:

- Prevents sudden equipment failure caused by oversized RAP materials.

- Work together to efficiently crush large RAP blocks.

- High wear resistance and easy replacement.

- Prevents sudden equipment failure caused by oversized RAP materials.

Cold Feed Bin

- Split Design for Easy Transportation:

- Ensures effective volume and ease of transportation.

- Anti-Clogging Grid with Vibrating Motor:

- Maintenance-free design, effectively removes oversized materials and prevents material blockage.

- Special Bin Structure:

- Prevents material arching and ensures smooth material flow.

- Ensures effective volume and ease of transportation.

- Maintenance-free design, effectively removes oversized materials and prevents material blockage.

- Prevents material arching and ensures smooth material flow.

Vibrating Screen

- Dual Vibration Motor-Driven Linear Screen:

- Maintenance-free design with tensioned screens at both ends, allowing for easy maintenance and replacement.

- High-Frequency Vibrating Screen with Anti-Clogging Technology:

- Effectively solves fine aggregate adhesion issues.

- Maintenance-free design with tensioned screens at both ends, allowing for easy maintenance and replacement.

- Effectively solves fine aggregate adhesion issues.

Double-Roller Secondary Crusher

- Floating Double-Roller Design:

- Allows for adjustable discharge size and effectively prevents equipment failure caused by oversized RAP materials.

- Interlaced High-Wear-Resistant Teeth Plates:

- Effectively crushes oversized RAP materials.

- Allows for adjustable discharge size and effectively prevents equipment failure caused by oversized RAP materials.

- Effectively crushes oversized RAP materials.

Vibrating Screen

Criba Vibratoria

Peneira Vibratória

Linear Screen Driven by Dual Vibration Motors:

- Maintenance-free design with tensioned screens at both ends, allowing for easy maintenance and replacement.

- High-frequency vibrating screen combined with anti-clogging mesh technology effectively solves fine aggregate adhesion issues.

Criba Lineal con Motores de Vibración Dual:

- Diseño sin mantenimiento con tensado de mallas en ambos extremos, facilitando el mantenimiento y reemplazo.

- Criba vibratoria de alta frecuencia combinada con tecnología de malla antiobstrucción para resolver problemas de adhesión de agregados finos.

Peneira Linear com Motores de Vibração Dupla:

- Design livre de manutenção com telas tensionadas nas extremidades, facilitando a manutenção e substituição.

- Peneira vibratória de alta frequência combinada com tecnologia de malha antiobstrução para resolver problemas de aderência de agregados finos.

Double-Roller Secondary Crusher

Trituradora de Doble Rodillo Secundaria

Britador de Rolo Duplo Secundário

Double-Roller Secondary Crusher:

- Floating roller design allows adjustable discharge size while protecting the equipment from sudden failures caused by oversized RAP materials.

- Interlaced high-wear-resistant teeth plates effectively crush oversized RAP materials.

Trituradora de Doble Rodillo Secundaria:

- Diseño de rodillo flotante que permite ajustar el tamaño de descarga y protege el equipo de fallas repentinas causadas por materiales RAP de gran tamaño.

- Placas dentadas de alta resistencia al desgaste dispuestas en forma intercalada para triturar eficazmente los materiales RAP de gran tamaño.

Britador de Rolo Duplo Secundário:

- Design de rolo flutuante permite ajustar o tamanho da descarga enquanto protege o equipamento de falhas repentinas causadas por materiais RAP de grande porte.

- Placas dentadas de alta resistência ao desgaste dispostas de forma intercalada para triturar eficientemente materiais RAP fora de especificação.

Why Choose Our Vibrating Screen and Double-Roller Secondary Crusher?

¿Por qué Elegir Nuestra Criba Vibratoria y Trituradora de Doble Rodillo Secundaria?

Por que Escolher Nossa Peneira Vibratória e Britador de Rolo Duplo Secundário?

Efficient and maintenance-free design with high-wear-resistant components.

Adjustable discharge size with floating roller technology.

Anti-clogging mesh technology for better screening performance.

High crushing capacity for oversized RAP materials.

Diseño eficiente y sin mantenimiento con componentes de alta resistencia al desgaste.

Tamaño de descarga ajustable con tecnología de rodillo flotante.

Tecnología de malla antiobstrucción para un mejor rendimiento de cribado.

Alta capacidad de trituración para materiales RAP de gran tamaño.

Design eficiente e livre de manutenção com componentes de alta resistência ao desgaste.

Tamanho de descarga ajustável com tecnologia de rolo flutuante.

Tecnologia de malha antiobstrução para melhor desempenho de peneiramento.

Alta capacidade de britagem para materiais RAP fora de especificação.

Introducción del Producto

El Equipo de Trituración y Cribado de Rodillos para RAP RPS100 es un producto especializado de Fujian Tietuo Machinery Co., Ltd., desarrollado con base en años de experiencia en equipos de reciclaje en caliente para plantas de asfalto, y adaptado a los requisitos específicos del manejo de RAP (Pavimento Asfáltico Recuperado) en Global.

Ventajas de la Tecnología de Trituración y Cribado de Rodillos

Trituradora de Rodillo Único Duradera:

- Equipado con placas protectoras de materiales resistentes al desgaste para proteger las cuchillas estándar.

- Alta capacidad de trituración, excelente resistencia al desgaste y fácil reemplazo.

Baja Emisión de Polvo:

- El eje principal de baja velocidad reduce efectivamente las emisiones de polvo.

Trituración de Doble Rodillo Flotante:

- El diseño de doble rodillo flotante previene fallas del equipo causadas por RAP de gran tamaño.

Placas Dentadas Intercaladas Resistentes al Desgaste:

- Tritura eficazmente los materiales RAP sin causar adherencia.

Criba Vibratoria de Alta Frecuencia con Tecnología Antiobstrucción:

- Combina criba vibratoria de alta frecuencia con tecnología de malla antiobstrucción para resolver problemas de adhesión de agregados finos.

Trituradora de Rodillo Único Duradera:

- Equipado con placas protectoras de materiales resistentes al desgaste para proteger las cuchillas estándar.

- Alta capacidad de trituración, excelente resistencia al desgaste y fácil reemplazo.

Baja Emisión de Polvo:

- El eje principal de baja velocidad reduce efectivamente las emisiones de polvo.

Trituración de Doble Rodillo Flotante:

- El diseño de doble rodillo flotante previene fallas del equipo causadas por RAP de gran tamaño.

Placas Dentadas Intercaladas Resistentes al Desgaste:

- Tritura eficazmente los materiales RAP sin causar adherencia.

Criba Vibratoria de Alta Frecuencia con Tecnología Antiobstrucción:

- Combina criba vibratoria de alta frecuencia con tecnología de malla antiobstrucción para resolver problemas de adhesión de agregados finos.

Introdução do Produto

O Equipamento de Britagem e Peneiramento de Rolo para RAP RPS100 é um produto especializado da Fujian Tietuo Machinery Co., Ltd., desenvolvido com base em anos de experiência em equipamentos de reciclagem a quente para usinas de asfalto, adaptado aos requisitos específicos de manuseio de RAP (Pavimento Asfáltico Recuperado) na Global.

Vantagens da Tecnologia de Britagem e Peneiramento de Rolo

Britador de Rolo Único Durável:

- Equipado com placas protetoras de materiais resistentes ao desgaste para proteger as lâminas padrão.

- Alta capacidade de britagem, excelente resistência ao desgaste e fácil substituição.

Baixa Emissão de Poeira:

- O eixo principal de baixa rotação reduz efetivamente as emissões de poeira.

Britagem de Rolo Duplo Flutuante:

- O design de rolo duplo flutuante previne falhas do equipamento devido a materiais RAP de grande porte.

Placas Dentadas Intercaladas Resistentes ao Desgaste:

- Tritura eficientemente os materiais RAP sem causar aderência.

Peneira Vibratória de Alta Frequência com Tecnologia Antiobstrução:

- Combina peneira vibratória de alta frequência com tecnologia de malha antiobstrução para resolver problemas de aderência de agregados finos.

Technical Specifications

Especificaciones Técnicas

Especificações Técnicas

- Model: RPS100

- Power: 121 kW

- Production Capacity: 100 t/h

- Maximum Feeding Size: 800 mm

- Discharge Size: ≤ 32 mm

- Modelo: RPS100

- Potencia: 121 kW

- Capacidad de Producción: 100 t/h

- Tamaño Máximo de Alimentación: 800 mm

- Tamaño de Descarga: ≤ 32 mm

- Modelo: RPS100

- Potência: 121 kW

- Capacidade de Produção: 100 t/h

- Tamanho Máximo de Alimentação: 800 mm

- Tamanho de Descarga: ≤ 32 mm