What we offer

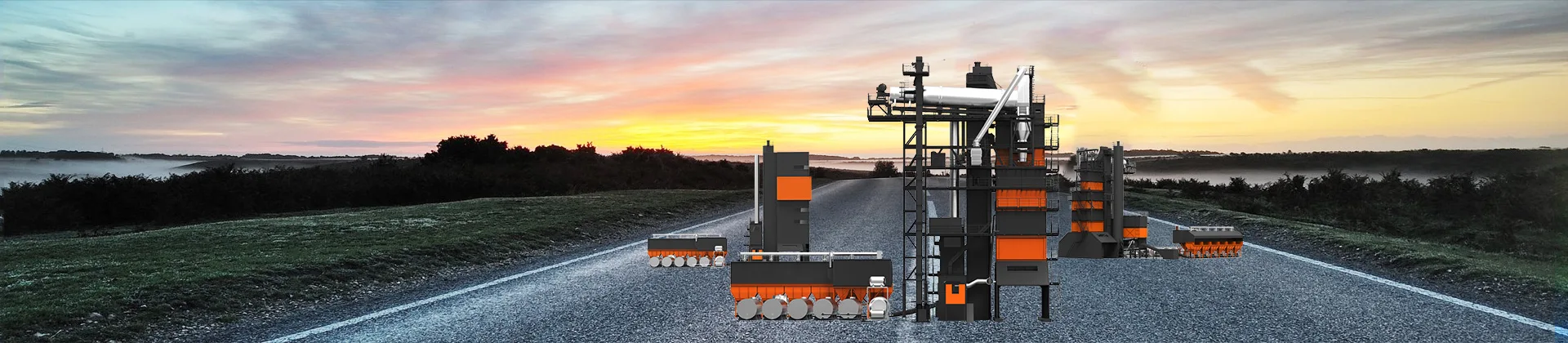

Asphalt Mixing Plant

The features for dedusting system: Modular design, the system is right above the dryer drum to save land and reduce heat loss by short pipes. The installation and site-transfer is easy.

1. Modular design for under-storage of ashpalt , 2. Easy to install and site-transfer, 3. Low failure rate.

1. Integrated and computerized design.

2. Easy for fuctions expanding,

3. Conveniently and reliable operation.

The linear vibration screen:

This important part vibration screen is run by double vibration motors of Italian brand. Free from maintenance. Front and rear gate, pull-insert installation of mesh, easy to replace.

The burner details:

The low-pressure burner is designed for the dryer drum with digital control on air/oil ratio and frequency, to ensure the better flame as per drum, to reduce oil consumption greatly. The burner control is integrated with plant control, easy to operate, safe and reliable. Suitable for diesel, heavy oil and natural gas.

Control system:

Double computer control with PLC, no button, full-auto control, easy to operate, user-friendly and reliable. The system comes with fault alarm and auto analysis, real-time monitoring and remote service.

The highlights for the asphalt facilities:

1. Integrated and computerized design,

2. Environmental friendly and Energy saving,

3. Conveniently and reliable operation,

4. Multiple languages operation system,

5. Low failure rate.

The highlights for the asphalt facilities:

1. Integrated and computerized design,

2. Environmental friendly and Energy saving,

3. Conveniently and reliable operation,

4. Multiple languages operation system,

5. Low failure rate.

The features for dryer drum:

The unified design of dryer drum, burner and bag house. The heat insulation is by silicate aluminum fibers, effective and environment-friendly.

The features for dryer drum:

The unified design of dryer drum, burner and bag house. The heat insulation is by silicate aluminum fibers, effective and environment-friendly.

The highlights for the bitumen plant:

1. Integrated and computerized design,

2. Environmental friendly and Energy saving

3. Conveniently and reliable operation

4. Multiple languages operation system

5. Low failure rate.

User water as foaming media, the unique mxixing machinery with position diaphragm pump imported will generate large amount of tiny foam that make it easy to mix the foam that make it easy to mix the foam evenly with mixture. The modular design makes it easy to install with great mixing effect, and less cost.

User water as foaming media, the unique mxixing machinery with position diaphragm pump imported will generate large amount of tiny foam that make it easy to mix the foam that make it easy to mix the foam evenly with mixture. The modular design makes it easy to install with great mixing effect, and less cost.

We have been accredited " The Enterprise of Double Customer Satisfaction, Product Quality Satisfaction and After sales Servives Satisfaction" by Committee of user of China Quality Management Asscociation in consecutive 5 years. More than 10 years experience, over 1200 successful cases in over 50 countries will help you succeed.

TTM has been accredited as "The Hi-Tech Enterprise in Fujian","The Provincial Innovation Enterprise in Fujian", "The Provincial Technology Center in Fujian", and "RAP Facility and Engeering R&D Center in Fujian".

TTM has ISO9001:2008, ISO1400:2007 and OHSAS 18001:2007, CE Certification, Chinese Military Quality Management System, CU-TR certification.We build our products based on management system and advance manufacturing by professional teams.

TTM has been accredited as "The Hi-Tech Enterprise in Fujian","The Provincial Innovation Enterprise in Fujian", "The Provincial Technology Center in Fujian", and "RAP Facility and Engeering R&D Center in Fujian".

The mixing part:

The mixer is twin-shaft mixer run by gearboxes with gear synchronization, simple and easy to maintain. The alignment and allocation of paddles achieve best mixing effects after yearly experience. The advanced manufacturing ensures the stability in performance. There is a safety lock at the inspection hatch to protect human. The mixer comes with heat insulation with diathermic oil and with inlet for SMA and RPA, easy for SMA and RAP machinery.

Control System Part:

Double computer control with PLC, no button, full-auto control, easy to operate, user-friendly and reliable. The system comes with fault alarm and auto analysis, real-time monitoring and remote service.

TTM has ISO9001:2008, ISO1400:2007 and OHSAS 18001:2007, CE Certification, Chinese Military Quality Management System, CU-TR certification.We build our products based on management system and advance manufacturing by professional teams.

TTM has been accredited as "The Hi-Tech Enterprise in Fujian","The Provincial Innovation Enterprise in Fujian", "The Provincial Technology Center in Fujian", and "RAP Facility and Engeering R&D Center in Fujian".

The mixing part:

The mixer is twin-shaft mixer run by gearboxes with gear synchronization, simple and easy to maintain. The alignment and allocation of paddles achieve best mixing effects after yearly experience. The advanced manufacturing ensures the stability in performance. There is a safety lock at the inspection hatch to protect human. The mixer comes with heat insulation with diathermic oil and with inlet for SMA and RPA, easy for SMA and RAP machinery.

Control System:

Double computer control with PLC, no button, full-auto control, easy to operate, user-friendly and reliable. The system comes with fault alarm and auto analysis, real-time monitoring and remote service.

1. Integrated and computerized design ;

2. Modular design for under-storage of asphalt, less land.